Elevator maintenance is not just good practice, it is required. Most states, including Texas, follow safety standards based on the ASME A17.1 Safety Code for Elevators. Local code enforcement may vary depending on region or building type, but the principle remains the same: elevators must be regularly maintained to protect passengers and reduce safety risks.

When elevators are not maintained, they fail more often. Doors may stop working correctly. The cab may stall between floors. Passengers may become stuck, and those breakdowns can cost more to fix than they would have to prevent. Routine maintenance extends the life of your equipment, lowers your long-term costs, and improves ride quality for every user.

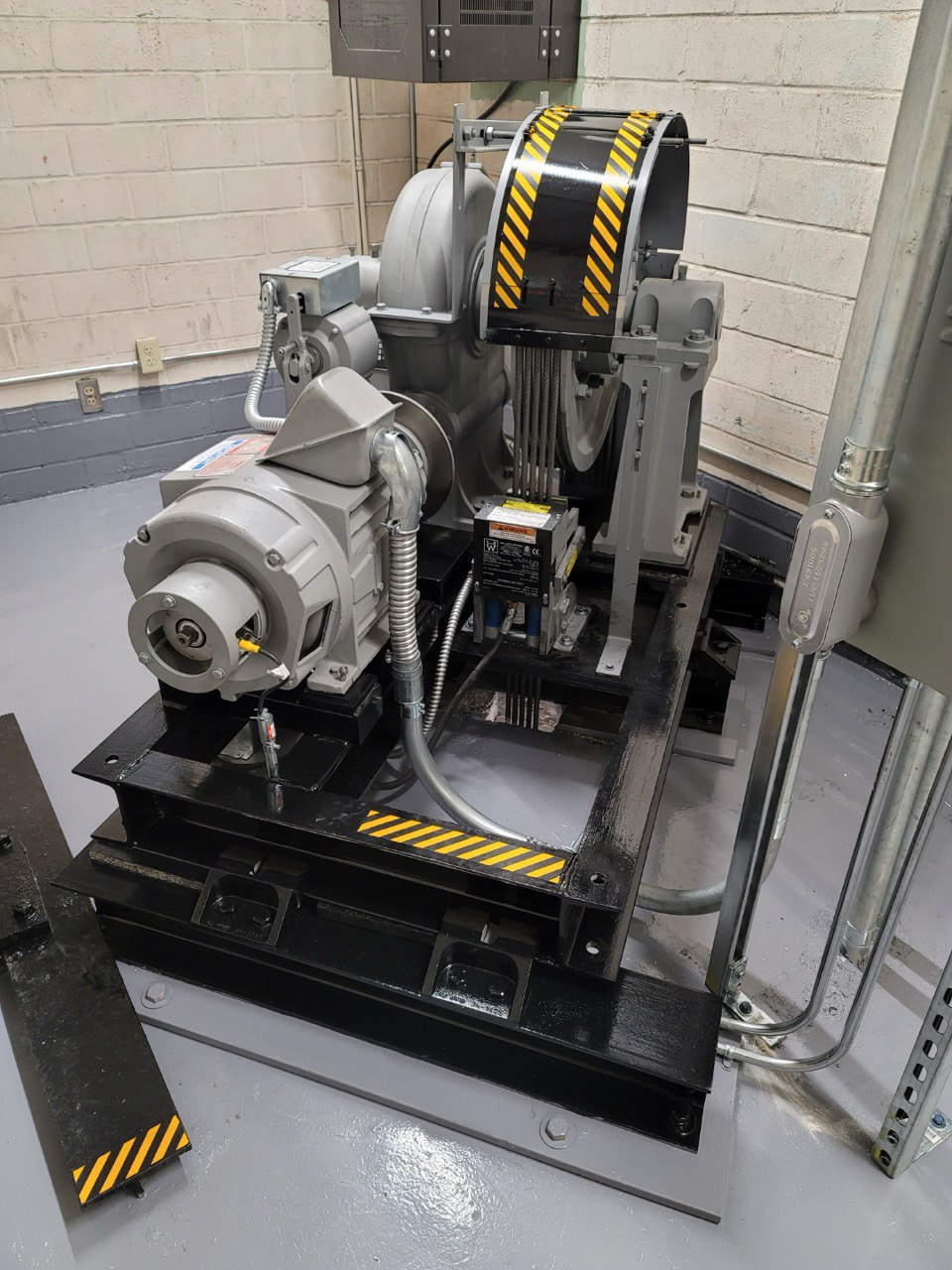

Every elevator is different, so no two service routines are exactly the same. Our technicians follow a maintenance control plan designed for the specific equipment, factoring in the age, usage, and environment. Common tasks include cleaning, lubricating, and adjusting mechanical components like the door operator, interlocks, roller guides, ropes, sheaves, brakes, safeties, and the governor.

We inspect areas that experience the most wear and catch early signs of failure. We also test key safety devices and controls to make sure the system is running within code requirements.

There is no one-size schedule. Some elevators in high-use buildings need service every month. Others, such as limited-use systems in smaller facilities, may be fine with quarterly visits. The right maintenance plan depends on how the system is used, how old it is, what kind of environment it operates in, and what the manufacturer recommends.

We will assess your system and help you build a plan that meets both code requirements and your operational needs.

Door equipment is the most common source of repair calls. That is because doors open and close more than any other part of the system. Sensors fail, rollers wear out, and interlocks become damaged—especially when doors are forced or obstructed. Malfunctioning door equipment often causes shutdowns, even when the rest of the system is functioning perfectly.

By keeping the door system cleaned, adjusted, and properly aligned, we can prevent many of these issues before they result in downtime.

Some elevators are back in service within an hour. Others take days or weeks, depending on what broke and how soon parts are available. Minor repairs can often be completed during the initial service visit. More complex problems, especially those involving older systems or custom equipment, may require extended diagnostics or ordering specialty parts.

Our job is to communicate clearly from the start. If a fix is immediate, we do it. If parts are delayed, we give realistic timelines and options. You will never be left guessing what is happening or how long it will take.

All of our repairs and maintenance are performed by qualified elevator mechanics. Our technicians have the training and experience to work safely and correctly on all major types of equipment. We know what it takes to meet inspection standards, pass code reviews, and maintain high-performing systems across a wide range of properties.

Whether you are setting up routine maintenance or calling about a shutdown, Boyer Elevator is ready to support your building with consistent, expert service. We work across Texas on systems large and small. We respond when needed and we keep you informed every step of the way.

📍 Proudly serving clients across Texas.

Call Boyer Elevator at (979) 221-1401 or contact us by this form to schedule a site visit.

Whether you are setting up routine maintenance or calling about a shutdown, Boyer Elevator is ready to support your building with consistent, expert service. We work across Texas on systems large and small. We respond when needed and we keep you informed every step of the way.

📍 Proudly serving clients across Texas.

Call Boyer Elevator at (979) 221-1401 or contact us by this form to schedule a site visit.

PO Box 41749

Austin, Texas 78704

Phone: (979) 221-1401

Email: [email protected]